Capabilities

Our Engineering Toolkit

We leverage a full suite of hardware, software, and diagnostic capabilities to design, build, analyze, and modernize systems of all kinds. These capabilities form the foundation of our R&D work and enable us to support legacy equipment, create prototypes, and develop custom solutions efficiently.

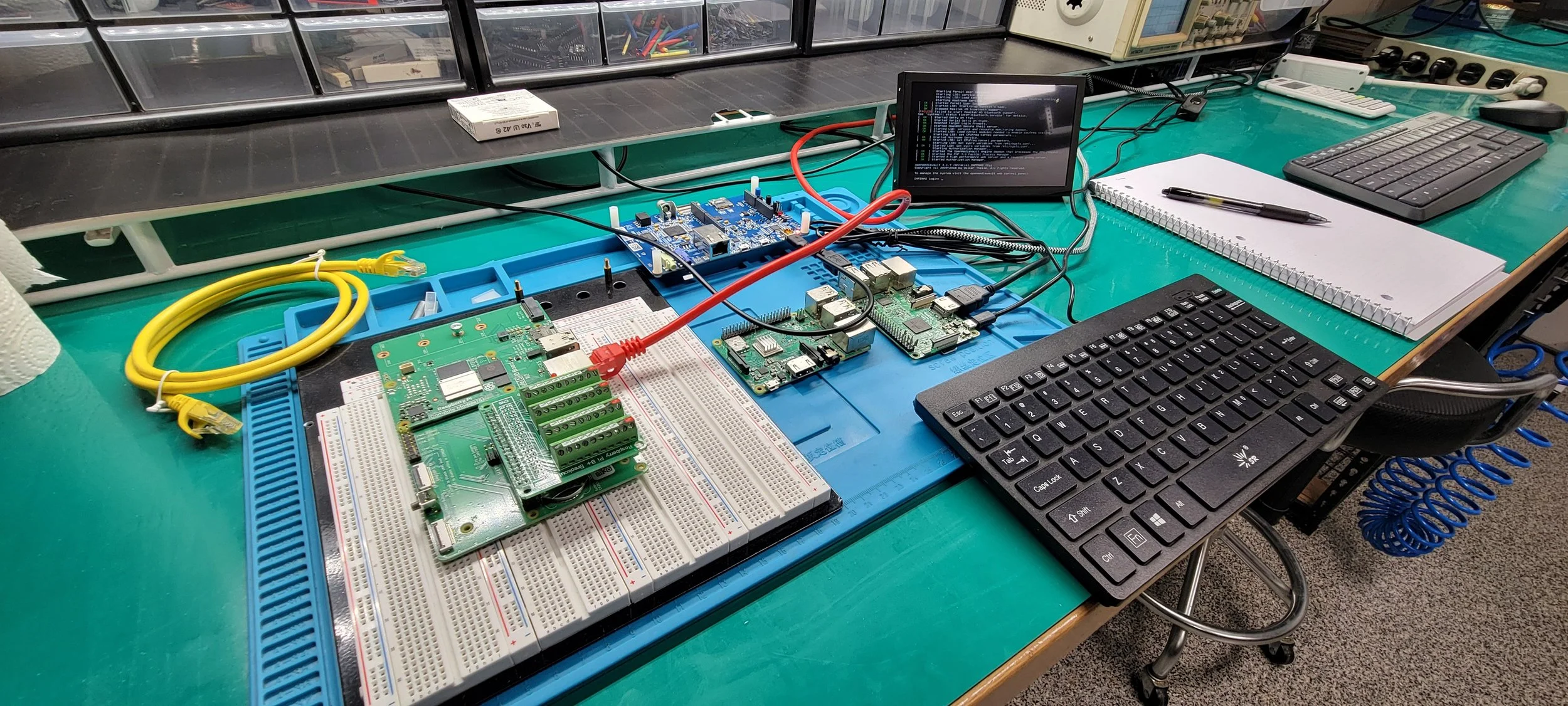

PCB Development

PCB design and layout (single-layer to multi-layer)

Rapid electronics prototyping (breadboards, dev boards, etc)

PCB assembly (hand, reflow, SMD prototyping)

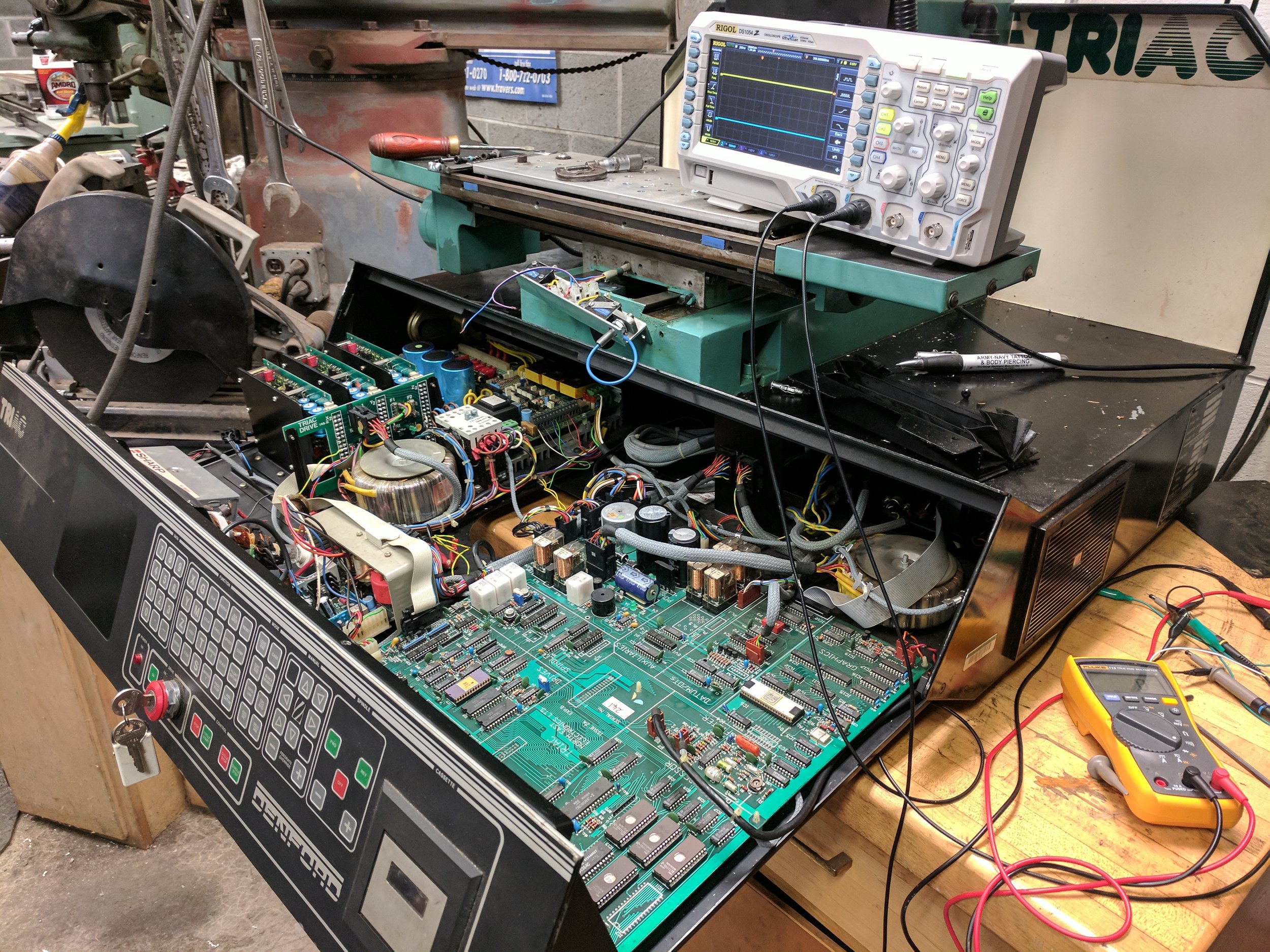

Reverse Engineering & Protocol Analysis

Schematic capture and circuit design

Reverse-engineered schematics and pinouts

Additive & Subtractive Fabrication

3D printing (FDM/Resin) for enclosures, adapters, brackets, and prototypes

General CNC milling for custom panels, fixtures, and hardware components

Laser cutting/engraving

Custom Electrical Development

Microcontroller and embedded system development

Mixed-signal circuit development (analog + digital)

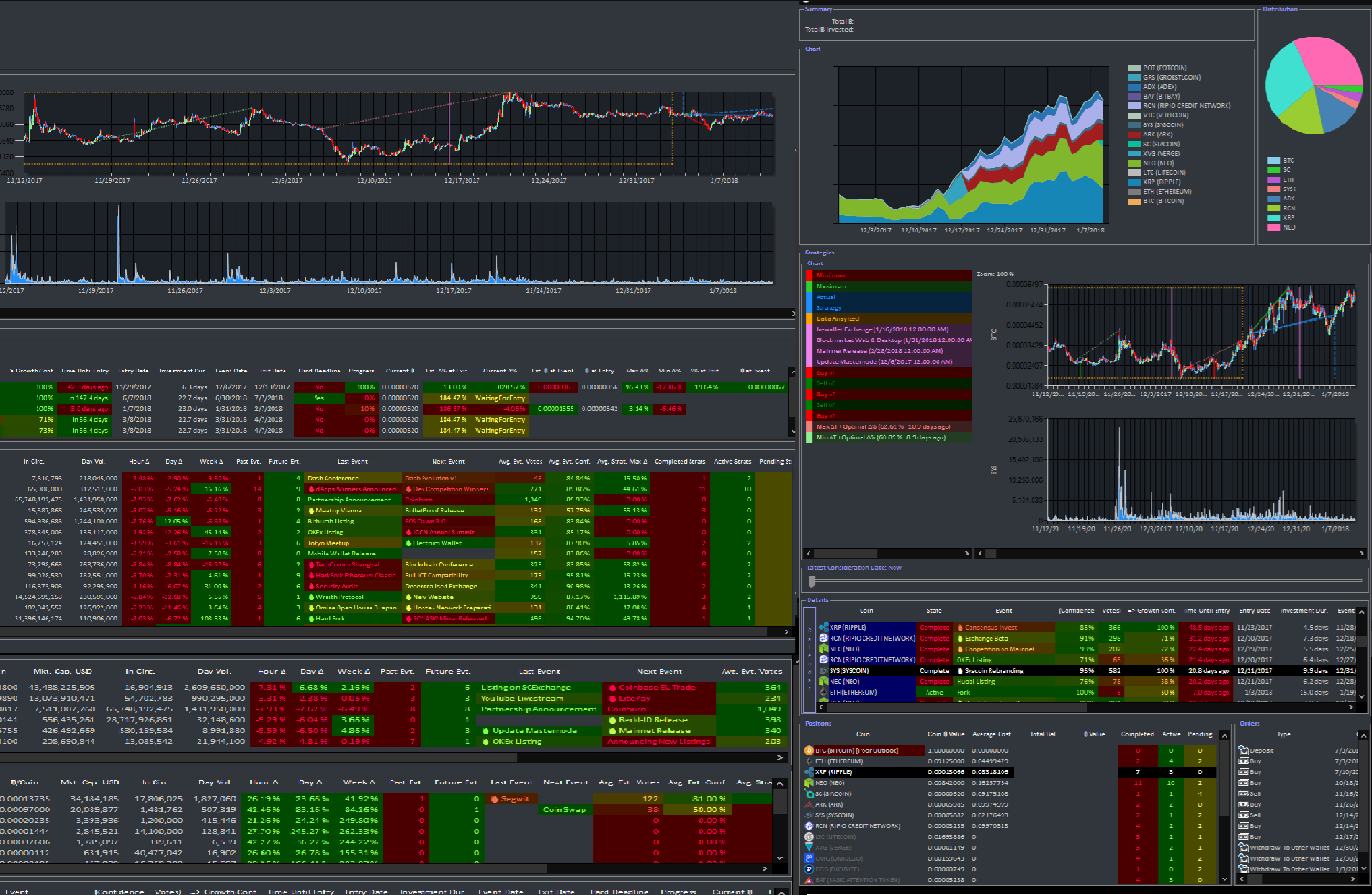

Custom Software Development

Desktop application, middleware, and API integration

Web-based dashboards, simple UIs, and reporting tools

Embedded-to-PC or embedded-to-cloud communication

Embedded firmware development

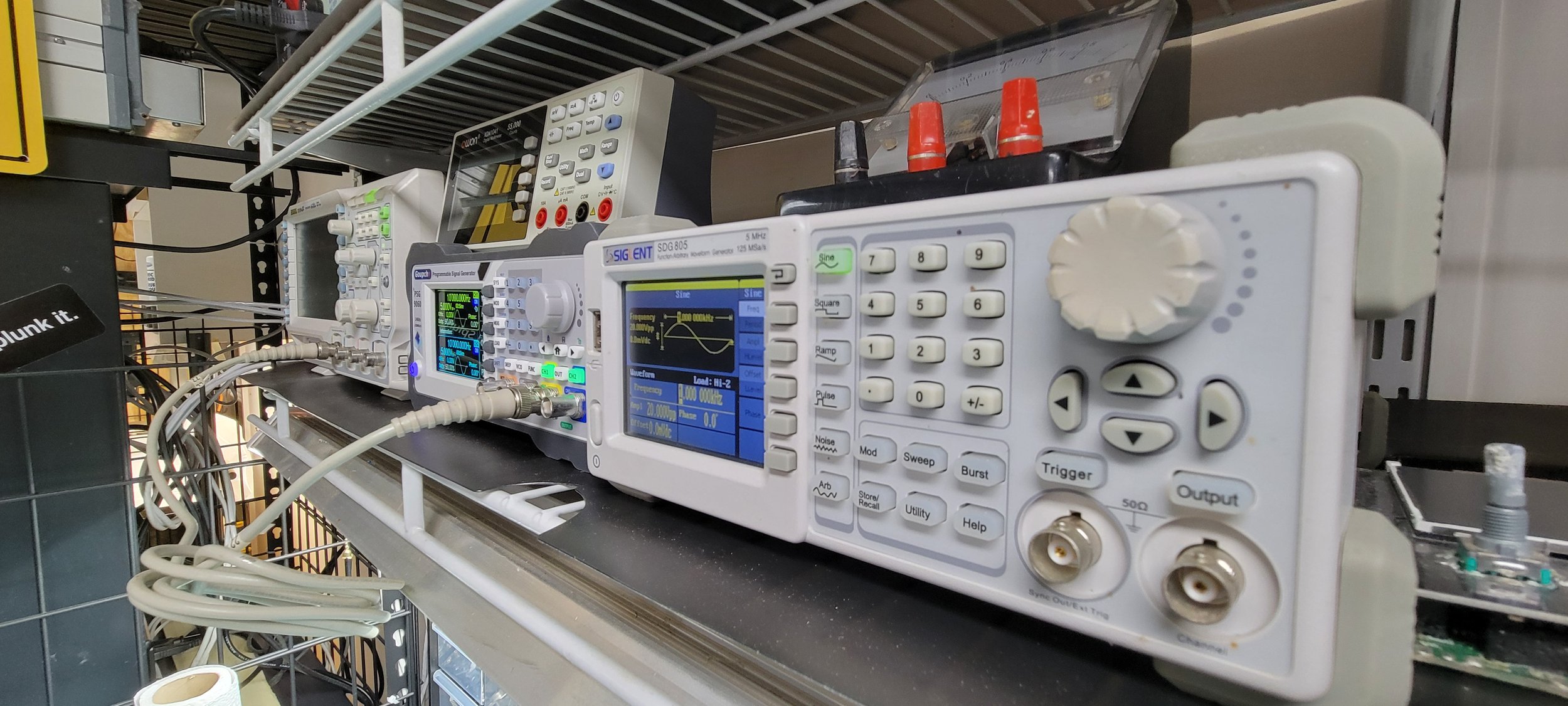

Signal Analysis & Diagnostics

Oscilloscope, logic analyzer, and protocol analyzer expertise

Reverse engineering unknown signals or protocols

RS-232, RS-485, CAN, I²C, SPI, Modbus, Ethernet, USB, custom/legacy

General Mechanical Design

Mechanical design using CAD

Controlled test rigs and automated test tools

Custom enclosure design and modification

Proof-of-concept hardware fabrication

Full-Stack Solutions

Sensor-to-Cloud Solutions

Multi-layer solutions

Legacy Data Modernization

Complete Embedded/Prototype Devices